Little Known Facts About Tx Tees.

Little Known Facts About Tx Tees.

Blog Article

A Biased View of Tx Tees

Table of ContentsSome Known Questions About Tx Tees.Tx Tees Fundamentals ExplainedIndicators on Tx Tees You Need To KnowThe Definitive Guide for Tx TeesIndicators on Tx Tees You Need To KnowExcitement About Tx TeesTx Tees Things To Know Before You Get This

That brings your total amount to about $1,900 gross and shipping. Build up various other expenses, like the number of energies it takes to run the shop and the cost of ink and solution per layout. t-shirt printing. Take the print below. This is a one-color photo, so the price of ink per tee shirt is roughly 20 cents.The solution ought to just be a few cents because you 'd only need to layer one display for this job. Generally, printers attempt to make up to 45% revenue on a print work.

With DTF, you can print a handful of t shirts, or simply one. Make use of the very same calculator as the area over to determine just how much revenue you 'd use DTF transfers. Contrast the expenses and revenues to whichever technique speaks ideal to your configuration and procedure. Both screen printing and DTF have their niches worldwide.

Tx Tees for Beginners

The finest way to understand? Ask about and see what printing shop like yours are doing. custom monograming. Try both out and see which you like much better

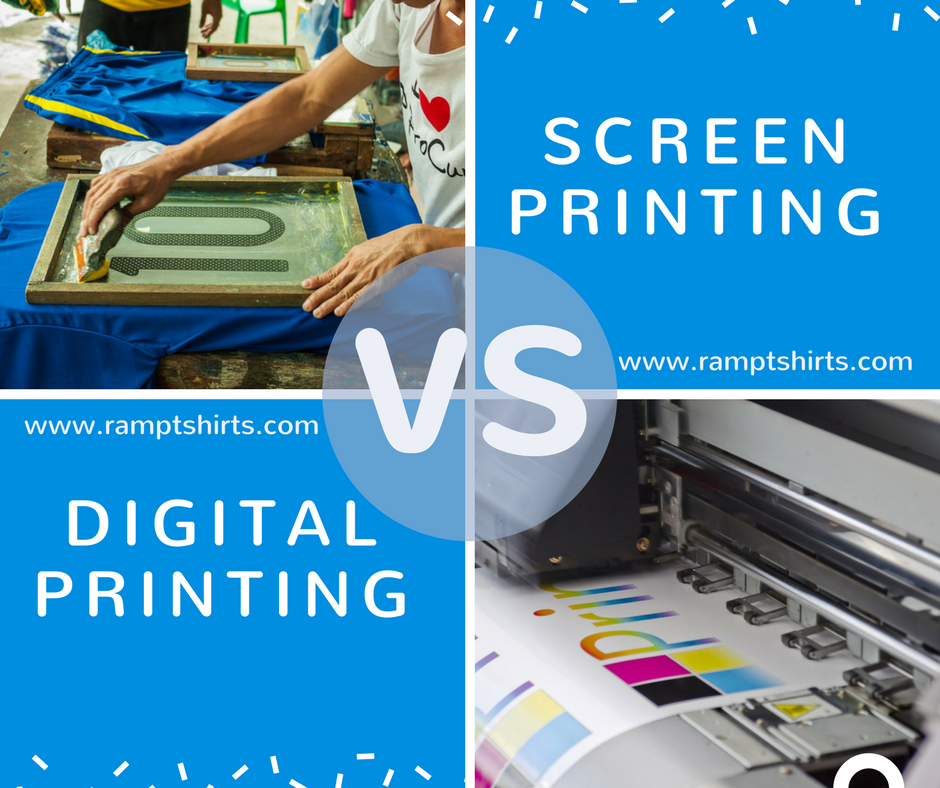

When you're picking what kind of printing method to utilize for publishing your art work layouts on your garments, it's essential that you recognize the distinctions in between these 2 techniques so you can optimize outcomes while minimizing costs. Screen printing is one of the most typically utilized method for printing styles on fabrics.

DTG printing is likewise called place or straight to garment printing since it publishes just what is required rather than making a screen as screen printers do. https://worldcosplay.net/member/1743892. Display printing works by screen filler squeegee screen printing ink display mesh display, then transferring the image to garment making use of heat and/or stress

The DTG printer uses special dye-sublimation inks that are applied right into a pre-designed picture by an electronic printing system. The inks end up being part of the material, permitting vivid shades and phenomenal detail. It's additionally referred to as place or direct to garment printing due to the fact that it prints just what is needed as opposed to making a display as screen printers do.

Tx Tees for Beginners

Initially, it's much faster - you can print a fullcolor picture in minutes, instead of hours for display printing. Second, there's no set up time or costs included - you can print any kind of layout you such as, without having to develop a display. Third, there's no waste - due to the fact that screen printers screen print one layout at once, they need to evaluate each shade independently.

The paper is really pricey and can only be made use of once. Once it's printed on, it needs to be disposed of. - The preliminary purchase rate is less than the in advance financial investment of DTG printers- You can publish multi-color styles one screen at a time rather than having to print each shade independently like DTG printing.

The Best Strategy To Use For Tx Tees

Nonetheless, as opposed to making use of screen mesh as screen printers do, color sublimation printers make use of laser technology to transfer your photos onto garments or paper. A warm procedure moves the dye from its solid-state directly right into the gas stage which subsequently fuses it onto material substratums when they are rapidly heated to heats under high stress.

Sublimation printing is environment-friendly. It makes use of much less water than screenprinting, and because it doesn't include using unsafe solvents, it's safe for all types of clothing. The dye sublimation inks are likewise unsmelling when healed, unlike display printers that use dangerous chemicals throughout the display printing procedure that leave an undesirable odor.

They also save cash on pricey equipment like exposure systems because dye sublimation printers don't need a UV direct exposure device or a flash treatment stove that is commonly utilized in screen printing (t-shirt printing). What is direct to garment printing (DTG Printing)? DTG printing is a digital screenprinting process that publishes straight onto material utilizing specialized inkjet printers

Some Known Questions About Tx Tees.

DTG printing uses lots of benefits over traditional screenprinting, consisting of the ability to additional resources publish photographic quality photos, higher color vibrancy, and the ability to publish designs on darker materials. DTG printers work by heating up the fabric ink till it becomes a gas. The gas then penetrates the material, bonding with the fibers to create an irreversible print.

Screen printers simply prepare their display after that begin printing up until they run out of product or ink.- There is a large range of experienced display printers throughout the world, which can be valuable for newbies. - It's a slower process - screen printers commonly have to wait on the ink to dry before they can print the next color- Display printers need manual work, so there's a higher knowing curve and it takes longer to generate a high-grade layout- Screen printing isn't as accurate as DTG printing, so you may obtain some "bleeding" of shades from one part of the image onto an additional if not done properly.

What Does Tx Tees Mean?

Rather of using display mesh as screen printers do, dye sublimation printers make use of laser technology to transfer your photos onto garments or paper. A warm procedure transfers the dye from its solid-state straight right into the gas stage which consequently integrates it onto fabric substrates when they are swiftly heated to high temperature levels under high pressure.

Sublimation printing is environment-friendly. It makes use of less water than screenprinting, and since it does not include using unsafe solvents, it's safe for all kinds of clothing. The dye sublimation inks are additionally odorless when cured, unlike screen printers that utilize unsafe chemicals during the display printing procedure that leave an undesirable smell.

They also conserve cash on pricey equipment like exposure units since dye sublimation printers don't need a UV direct exposure system or a flash treatment oven that is typically used in screen printing. What is direct to garment printing (DTG Printing)? DTG printing is a digital screenprinting procedure that publishes straight onto textile making use of specialized inkjet printers.

Tx Tees for Dummies

DTG printing offers several advantages over standard screenprinting, consisting of the capability to print photographic top quality photos, higher shade vibrancy, and the capacity to print designs on darker textiles. DTG printers function by heating up the textile ink until it transforms right into a gas. The gas then penetrates the textile, bonding with the fibers to develop a long-term print.

Report this page